35

Pump Technology Ltd. can specify and

supply a wide range of

MACERATOR, SEWAGE, DRAINER &

WASTE WATER PUMPING SYSTEMS.

56 Youngs Industrial Estate, Aldermaston, Berks. RG7 4PW

Tel: 01189 821555 Fax: 01189 821666

E-mail:

Web Site:

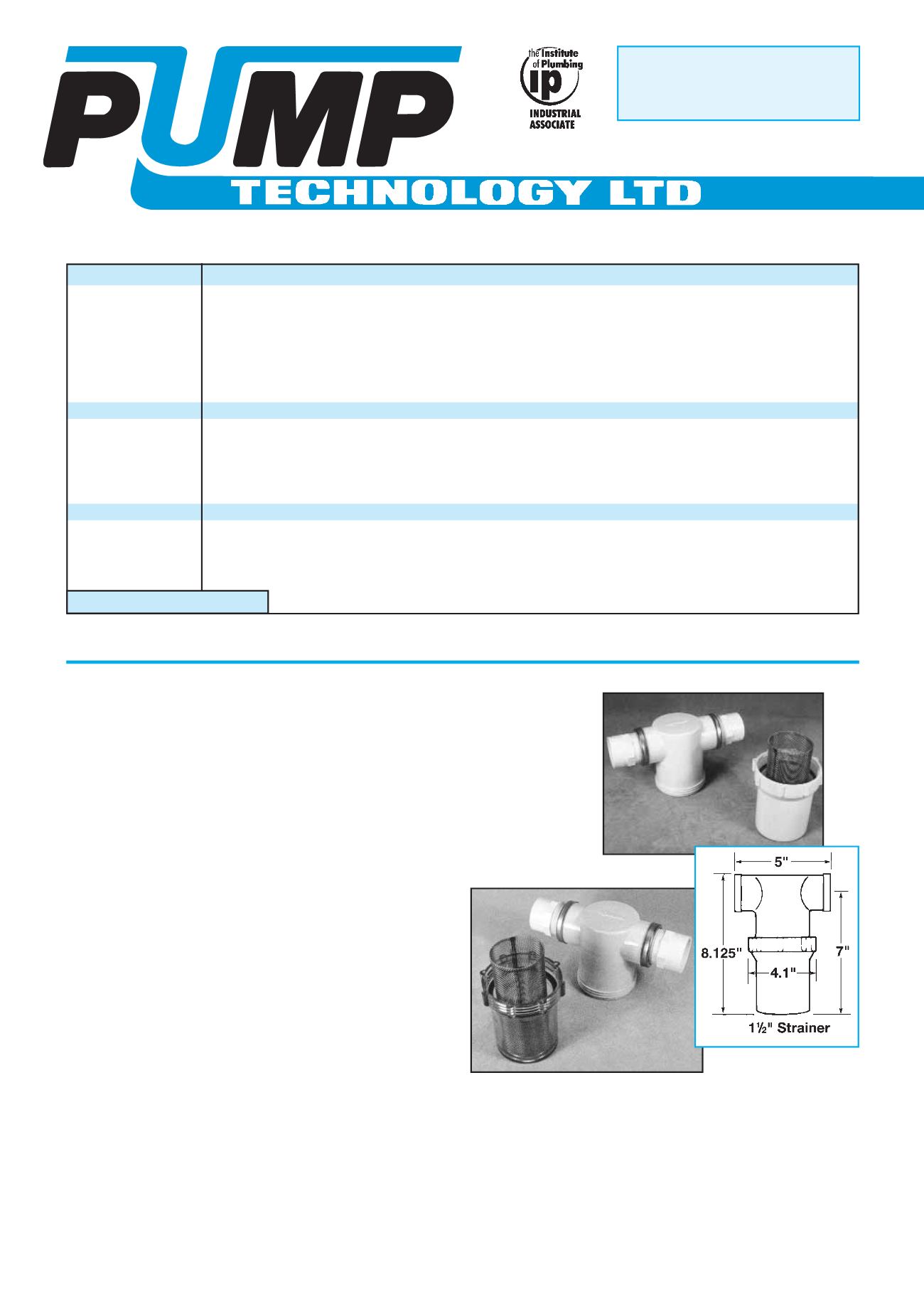

IN-LINE STRAINERS

(PTL-1LS)

Suitable for DRAINMASTER, DRAINMAJOR

and DRAIN - KING Waste Water Pumping

Systems with Cleaners’ Sinks and

Hairdressers Hand basins.

(Not suitable for Kitchen Sinks with grease)

SPECIFICATIONS

The PTL-1LS in-line strainer is available in two versions.

1. Opaque white bowl

2. Clear polymide bowl which allows for visual

inspection of strainer (must not be used with

alcohol)

Both strainers have 1½" BSP female threaded

connections to which are fitted plastic to male iron

adaptors for solvent weld 1½" plastic waste pipe.

Filter screens are 20 mesh stainless steel which are

easily removable for cleaning.

Ratings: 150 psi at 70°F, 100 psi at 125°F.

(140°F is the maximum temperature.)

INSTALLATION

Install the line strainer on the inlet side of the pump.

The arrow moulded in the strainer cap indicates flow

of liquid.

Waste Water

Head 1m 2m 3m 4m 5m 6m 7m 8m 9m 10m 11m 12m

PTL30 & 30SL

l/s

1.7 1.5 1.4 1.1 0.8

PTL303E

3.8 3.5 3.2 3

2.5 2

1.6 1

PTL60E

4.2 4

3.6 3.2 2.6 1.8 1.2 0.6

PTL60D

4.6 4.4 4.2 3.7 3.2 2.7 2

1.1

PTL730E

5.2 4.8 4

3.2 2.8 2.2 1.7 1

PTL730D

6

5.1 4.6 4

3.5 2.8 2.2 1.8 1

PTL1030E+D

8

7.4 6.8 6

5.2 4.8 4

3.5 2.8 2.2 0.7

Sewage Vortex

Head 1m 2m 3m 4m 5m 6m 7m 8m 9m 10m 11m 12m

Midi 40E + D

l/s

14 13 12 10 6

4

Macro

12 10 8.5 5.5 3.5

Maxi 80&120E + D

15 13 9

7.5 5.5 3.5

Maxi 80&120/51D

18 17 15.2 13.8 12 10 7.5 5.5

Maxi 80&120/52D

15 14 12 8.5 6.5 3.8

Sewage Cutter

Head 6m 8m 10m 12m 14m 16m 18m 20m 22m 24m 26m 30m

Grinder 10/82E

Please check details with our Technical Team

Grinder 10/82D

Please check details with our Technical Team

Grinder 10/52 D

4.8 4.8 4.7 4.5 3.8 3.3 2.7 2

1.3

Grinder 10/53 D

4.5 4.2 3.9 3.4 2.2

E = 230v D = 415v 3 Phase

Pump Flow Rates

in Litres Per Second (l/s)

NOTE:

These flow rates are for static head only. Friction loss has to be calculated and added to static head to provide the final flow rate.

Please contact our Technical Department for best pipe size to provide best pump performance and desired flow rate.