28

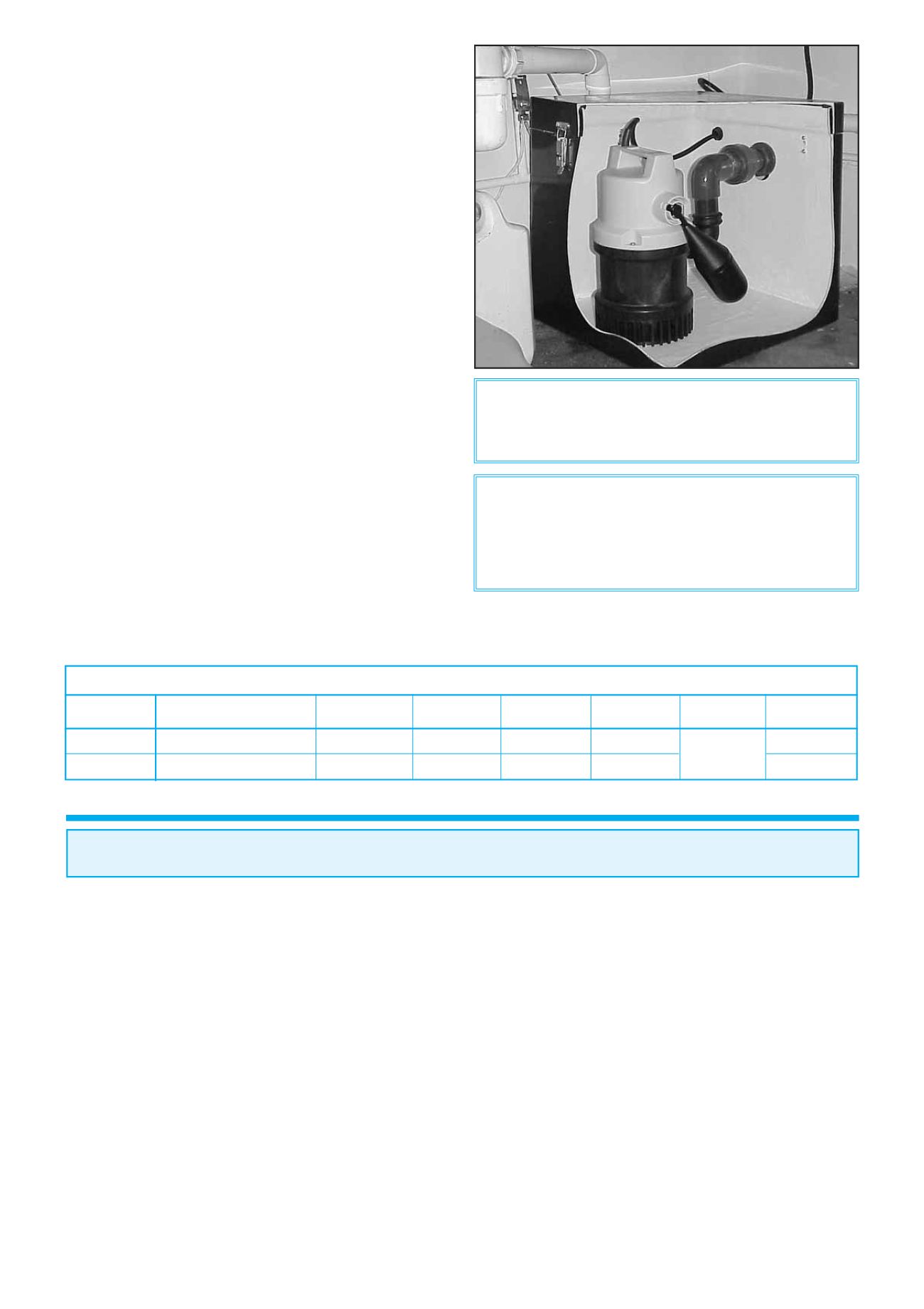

DRAINMAJOR 60:

The durable tank is manufactured from

polyester/glass fibre laminate, fully rigged with internal

pipework and non return valve.

QUALITY:

The tank is pigmented throughout with an

externally smooth isophthalic polyester gel coat and resin

enriched lining.

OUTLETS:

The tank has a 1¼" BSP male thread discharge

outlet. (NRV supplied is female thread).

PUMP Type PTL60:

Vertical centrifugal type, single stage for

submerged operation, with strainer base, open impeller (10

mm solids handling capacity).

Motor:

Fully encapsulated submersible motor with built-in

overload/thermal cut-out, watertight (IP68) enclosure, class B

insulation. Supplied with built-in level switch.

Pump Casing:

Plastic GFK pump body, top cover and GRP

impeller, stainless steel encapsulated motor.

Bearings:

Combined shaft for motor and pump, mounted in

grease lubricated ball bearings.

Shaft Seal:

Silicon carbide mechanical seal, unaffected by

dry running for short periods.

Fitted with mechanical seal and oil buffer chamber, the

pumps will give reliable service for long periods with

minimum supervision and maintenance, apart from regular

cleaning of the tank and pump strainer.

ALL INVERTS TO BE MADE TO SIDE OF TANK USING

TANK CONNECTORS.

1¼" MINIMUM VENT TO AIR REQUIRED.

IF DISHWASHERS, GLASSWASHERS OR WASHING

MACHINES ARE USED A 2" VENT IS REQUIRED.

The

DRAINMAJOR 60

comes complete with a one year

warranty. In the unlikely event of technical difficulties,

please ring:

Pump Technology Limited on 01189 821555

The

DRAINMAJOR 730

is recommended for kitchens

where

30mm solids handling

capacity is required (e.g.

for sinks with waste disposal units).

See page 25.

If your requirement is for commercial kitchens with multiple

sinks, dishwashers, glasswashers etc. please use the

DRAINKING.

Due to a policy of continuous product improvement we reserve the right to alter specifications without notice.

IMPORTANT: This unit is not designed to handle sewage. Please enquire about our

packaged sewage pumping systems.

INSTALLATION

DRAINMAJOR 60

Installers please note. (use solvent weld or copper pipe)

1.

Remove lid from tank, check pump is correctly positioned and connecting pipework has not been damaged in transit.

2.

Check that the pump is correctly positioned in the tank and that the union is tightly connected so that the pump does not

move on its mountings impeding the float action.

3.

All inverts should be brought into the side of the tank by drilling a hole and using an appropriate tank connector.

4.

All inverts should be brought into the tank (using tank connectors) at the highest possible level from the floor - i.e. no

lower than 200 mm from base of unit. (The addition of a low level float can reduce this to 110mm).

5.

Preferably no connections through the lid as this inhibits easy removal of the lid for cleaning tank. (Note: tank

MUST

be positioned in such a way that lid can be removed easily to allow access for tank interior and pump cleaning.)

6.

Ensure that the inflow of water is not directed onto the float mechanism.

7.

Slow radius bends MUST be used for every change of direction of the discharge pipework.

8.

If the discharge pipework connects to a soil stack, manhole etc.

below the discharge outlet of the tank

, an anti-syphon

unit MUST be fitted to the highest point of the discharge pipework.

VENTING TO AIR:

THE TANK MUST BE VENTED TO AIR (1¼" MIN.).

DO NOT USE A DURGO / AIR ADMITTANCE VALVE

.

IF GLASSWASHERS OR COMMERCIAL/INDUSTRIAL DISHWASHERS/WASHING MACHINES ARE USED IT IS

RECOMMENDED THAT AT LEAST A 2" VENT IS TAKEN TO AIR. (IF YOU WISH TO DISCUSS YOUR PARTICULAR

APPLICATION WITH REGARD TO VENTILATION PLEASE CONTACT OUR TECHNICAL SALES DEPARTMENT.)

MAINTENANCE:

The DRAINMAJOR 60 should have the lid REGULARLY removed for CLEANING of the Tank and Pump

PTL 60D

3-phase 400V

0.75kW

0.60kW

1.3A

2800

10mm

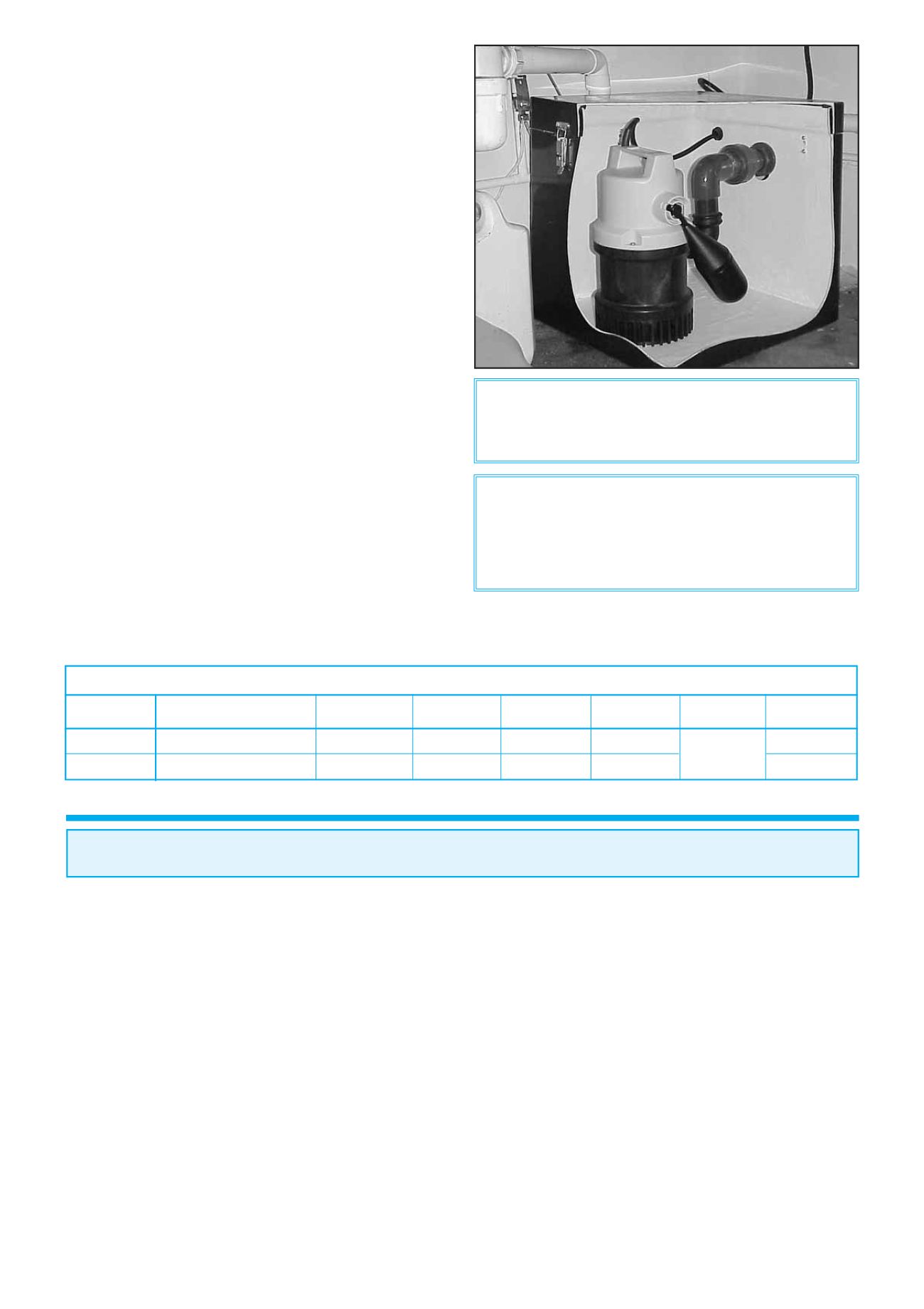

Technical Data (50 Hz)

Type

P1

P2

F.L.C.

RPM

Overload

Protection

Max. Solids

Size

Voltage

PTL 60E

single phase 230 V

0.70kW

0.45kW

3.4A

2600

10mm

Incorporated

in motor

(thermostat)

Depending on the working environment of the DRAINMAJOR it may be advisable to fit a grease trap/interceptor.

Please seek advice from our technical department.

For Flow Rates, see Page 35