18

Due to a policy of continuous product improvement we reserve the right to alter specifications without notice.

The EFFLU GRINDER 10:

Consists of a Polyethylene tank complete with a discharge

non return valve and couplings for all invert, discharge &

vent connections including reflux (non return valve).

The entire unit is damp and flood-proof and thus ideally

suited to placing in unventilated areas or basements subject

to accidental flooding.

It incorporates a Control Panel with overload relay, alarm

device, high level alarm and volt free contacts for remote

alarm.

Install Control Panel in dry area.

The

EFFLU GRINDER 10

comes complete with a

one year warranty. In the unlikely event of technical

difficulties, please ring:

Pump Technology Limited on

01189 821555

Other products in the series include:

EFFLU MIDI, EFFLU MACRO & EFFLU MAXI

Single Pump Sewage Disposal units.

TECHNICAL DATA

EFFLU GRINDER 10

PERFORMANCE

DESCRIPTION

Pump:

Single stage vertical centrifugal pump, with open 3-blade impeller, horizontal 1½" flanged discharge branch, and

adjustable Multicut cutting system.

Shaft/Bearings:

Combined pump/motor shaft, protected against contact with pumped liquid, and rotating in grease-packed

ball bearings.

Shaft seal:

Oil-filled seal chamber between pump and stator casing with wear-resistant silicone carbide primary seal with dry

running properties and duplex lip seal as secondary seal.

Motor:

Submersible motor with "dry" type stator windings class F insulation, watertight cast iron enclosure (IP 68) supplied

with multicore flexible cable with polychloroprene outer sheath. The pumps are also available with explosion-proof motors

(EEx dll BT4) in accordance with German specification V.D.E. 0171.

Materials:

Cast iron pump and motor casings and impeller, corrosion protected shaft (no contact with pumped liquid) stainless

steel hardened (HRC 57) cutting system.

Maintenance is extremely simple:

the tank has a top mounted inspection/cleaning aperture and, if necessary, the pumping

unit can be removed/replaced in minutes and without disturbing the tank assembly.

The GRINDER System

The liquid flows into the impeller through a rigid,

perforated cutter plate in which apertures are tapered

to improve the suction performance.

The sharpened three bladed cutter, rotating in front of

the inlet, shears any solids present. The impeller

passes these through a counterflow system in the wear

plate, then into the volute casing and out through the

pump discharge.

The cutter plate rejects any material such as stones or

metal that it is unable to cut. The combined cutting and

pumping system gives trouble-free, low-cost sewage

disposal even with difficult ground conditions.

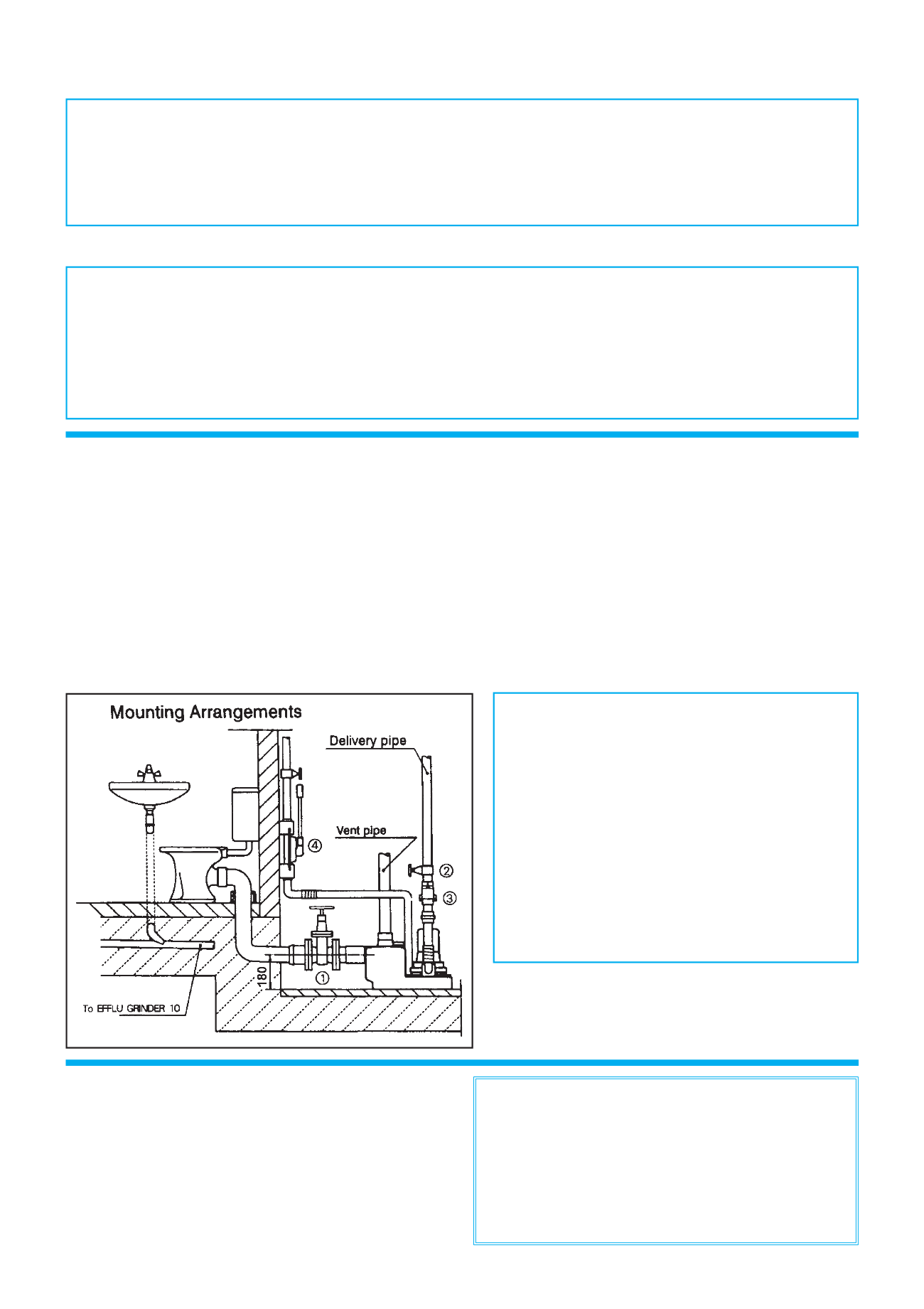

KEY

1.

Sluice Gate Valve / (inlet) -

optional

2.

Sluice Gate Valve / (discharge) -

optional

3.

Reflux Valve / Non Return Valve -

supplied

4.

Hand Diaphragm Pump -

optional

EFFLU Tank Capacity -Litres

Floor to Centre Inlet

Inlet Flange

Weight kg max.

GRINDER TYPE

10/82

38

180 & 250

100mm

41

10/52

38

180 & 250

100mm

52

10/53

38

180 & 250

100mm

52

EFFLU

Voltage

Motor Rating

Current

Motor

RPM

Vent

GRINDER TYPE

KW in - KW out

Ampere

Protection

10/82E

230

1.7 1.14

7.5

in Control Panel

2584

70mm

10/82

400

1.65 1.24

2.8

in Control Panel

2694

70mm

10/52

400

2.6 2.1

4.4

in Control Panel

2800

70mm

10/53

400

3.7 3.1

6.6

in Control Panel

2885

70mm